Contact Web Cleaners

Machine-mounted ContactClean™ Web technology that removes contaminants from the web surface cost effectively and efficiently—reducing down time and waste while improving productivity and product quality.

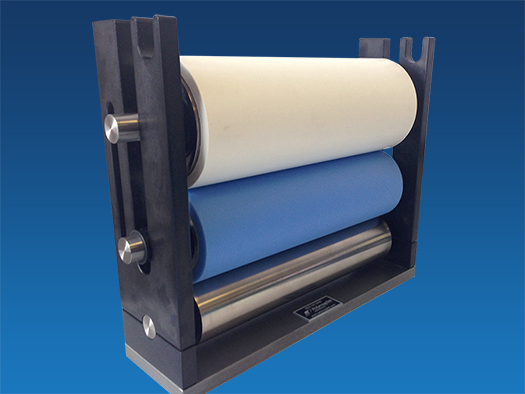

Single-Side, Top-Side Web Cleaner with Pneumatics

Simple and robust, this web cleaning system incorporates proven technology at a cost-effective price.

This single-side, top-side web cleaner mounts to your side-frame or dead-shaft idler roll. The Contract Cleaning Roll (CCR) creates a gravity nip along a horizontal web plane with the idler roll to remove contaminants from web surfaces.

More Details Connect With a Rep

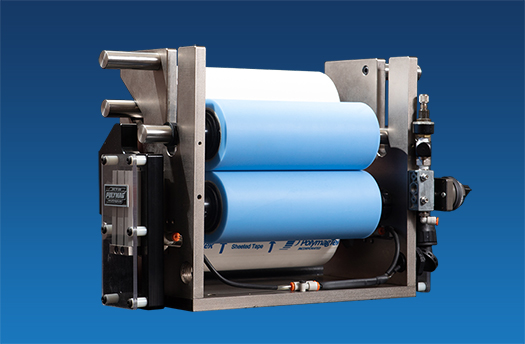

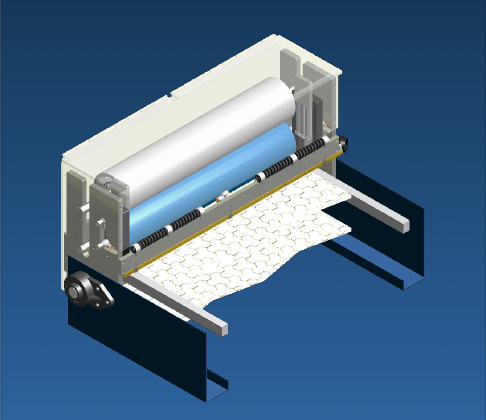

2-Sided Web Cleaner with Roll Separation Pneumatics

The "workhorse" of the contact web cleaning world. Two-sided contact cleaning technology at a fraction of the cost. Simple, maintenance-free, industrial design with large Contact Cleaning Rolls (CCRs).

More Details Connect With a Rep

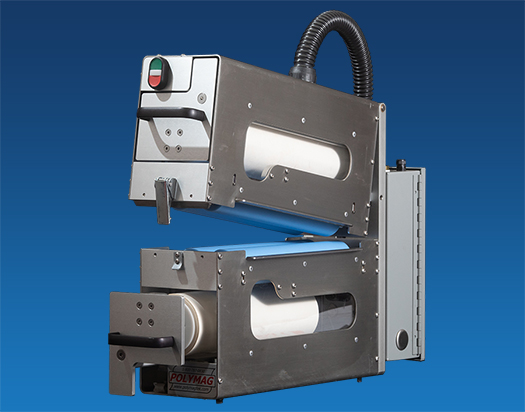

Two-Sided, Single-Nip or Double-Nip Web Cleaner

Two-sided, contact web cleaning for continual run, stop-and-go or limited-access applications, including slitters, coaters, die-cutters, laminators, presses, embossers or more.

More Details Connect With a Rep

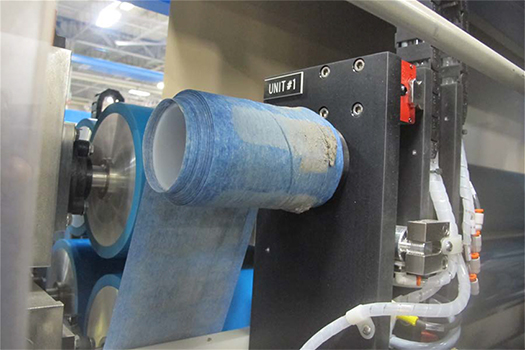

Dual Offset Tape Roll, Wide Web Cleaner

Robust, innovative and configurable, this wide web contact cleaning system provides two-sided cleaning for webs wider than 60" (1,524 mm) and up to 118" (3,000 mm) at speeds up to 800 fpm.

More Details Connect With a Rep

Nip-to-Nip Traversing Wash Web Cleaner with Oscillation

This web cleaner cleans both sides of a substrate utilizing a contact cleaning roll nip in the vertical span of the web.

More Details Connect With a Rep

Nip-to-Roll Water Wash Web Cleaning

This web cleaner captures loose contamination on the web and then transfers it to the CCR.

More Details Connect With a Rep

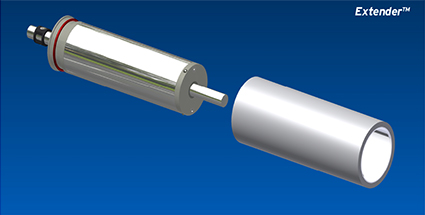

Extender™ Self-Contained Oscillating Tape System

This self-contained, oscillating tape roll system traverses 1.5” (38mm) across the face of the Contract Cleaning Roll (CCR), thereby eliminating the “line of travel” caused by slit edge contamination.

More Details Connect With a Rep

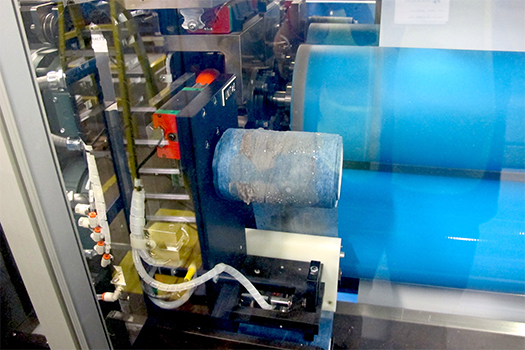

Conveyor Cleaner

This system offers in‐line conveyor cleaning without adversely impacting operational efficiency.

This system removes contaminates from a moving conveyor by utilizing Contact Cleaning Rolls (CCR). The contaminants are then transferred from the CCRs to a sheeted adhesive tape roll for permanent elimination.

More Details Connect With a Rep

Static Clean WebVac

This WebVac Web Cleaning System from Static Clean is a continuous-duty cleaning system designed to provide contact or non-contact cleaning of narrow and wide webs in a variety of critical applications.

More Details Connect With a Rep

Frequently Asked Questions

Polymag® Tek has options for thin or sensitive substrates. Our experience has shown that nipping a contact cleaning roll against an idler instead of another contact cleaning roll is the preferred configuration for a thin substrate. See 2SNR-WC-IIA or 2SNR-WC-DS

Most Polymag® Tek machines can handle web speeds up to 800 feet per minute. For webs moving faster than 800fpm, there are some design considerations that we can adjust to handle the faster speeds. We use low drag bearings on all of our rollers. We can increase the roll OD and modify the web path to ensure consistent contact and effective cleaning.

Many customers are using a slit product, or are slitting themselves. The highest amount of contamination is generally on the edges of the slit product.

To combat the higher levels of contamination in these particular areas, Polymag® Tek has developed The Extender™ self-oscillating tape roll assembly. This assembly moves the adhesive tape roll back and forth in the transverse direction to spread where the concentrated areas of contamination are located. This leads to longer adhesive tape life.

Additionally, if a customer is looking for a web cleaner on a slitter, we have designs that can accommodate the adjustable web width and slitting locations. If the web is being split into multiple webs or rewinds, we can install a cleaner close to the knifes before the web is split apart, or locate cleaners on each slit section.

Paperboard in general terms is a very dirty substrate. Clay coated or recycled paperboard is even more so. Because of the high levels of contamination, traditional web cleaners that use a Contact Cleaning Roll and Adhesive Tape combination is not very cost effective. The adhesive tape loads up with contamination fast, leading to a high consumables cost.

Polymag® Tek’s solution to this problem is our Oscillating Water Wash Web Cleaners. NN-OWC/NR-OWC. These cleaners use a pair of contact cleaning rolls that are rotated between cleaning the web and being washed with a robotic cleaning head. Contamination is collected on a wet sponge backed cloth. Our Water Wash systems are the only cleaners on the market that can cost effectively clean paperboard products.

Many customer use an intermittent process where the web is indexed for punching, die cutting, sealing or pouch making. Polymag® Tek has taken this into consideration by actively seeking to reduce the tension loss on the web. We accomplish this by using a “gravity nip” in most of our machines.

In the gravity nip, the top roller sits in a slot and is not loaded against the web. The only force against the web is the weight of the contact cleaning roll and adhesive tape. The tension loss for these systems is less than 0.04 PLI, making these machines ideal for intermittent processes.

Laminating usually requires two cleaners or cleaning stations. Most customers want to clean the bottom of the top web and the top of the bottom web so that no contaminants are trapped in between layers. We work with these customers to design cleaners that meet their needs and prevent trapped defects.

Pouch making is similar to the laminating process. The critical aspect of cleaning is to ensure the “contact surfaces” on the inside of the pouch are clean and clear of defects. This usually requires two cleaning stations.