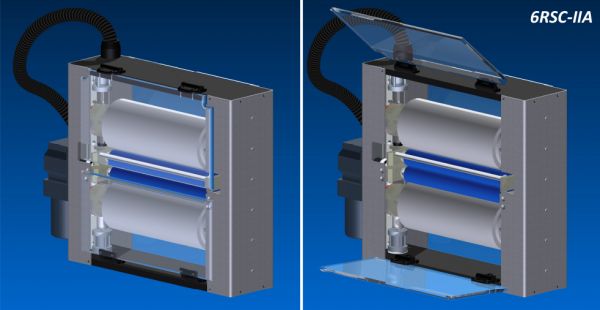

Two-Sided, Double-Nip Sheet Cleaner with Roll Separation Pneumatics

This system offers customized sheet cleaning to meet unique needs.

Contact Cleaning Rolls (CCR) remove contamination from the sheet and then transfer it to adhesive tape rolls. Custom in-feed and exit conveyors are available to establish the most efficient sheet cleaning process.

Applications

- 2 Sided Sheet Cleaning

- “Double Nip”- up to 99.9% efficiency

Process Parameters

- Sheet widths up to a maximum 30”

- Standard speed up to 30 fpm

Features

- 2‐sided, gravity, double‐nip design

- 1.25” O.D. Contact Cleaning Rolls (CCRS)

- 3.0” I.D. Core, Pre‐Cut, Sheeted Adhesive Tape Rolls

- Customizable in‐feed and exit conveyors for various substrates

- Pneumatic cylinders to separate rolls when machine stops

- Hinged polycarbonate guard doors for easy tape access

- Active Static Elimination on exit side

- Alternate designs available

- Stainless Steel and Aluminum construction

Options

- In-feed active static elimination

- Various conveyor configurations

- Thin film transport system

- Variable speed motor drive

- Jackshaft drive